Laser Cutting

Service Steel has been supplying customers with Laser Cutting Services for 100 years.

We pride ourselves in knowing our customers’ needs as well as they do.

The Service Steel has been supplying customers with Laser Cutting Services for 100 years. We pride ourselves in knowing our customers’ needs as well as they do.

SERVICE STEEL OFFERS THE LASER CUTTING SERVICES THAT YOU NEED

There are numerous benefits in choosing our laser cutting services

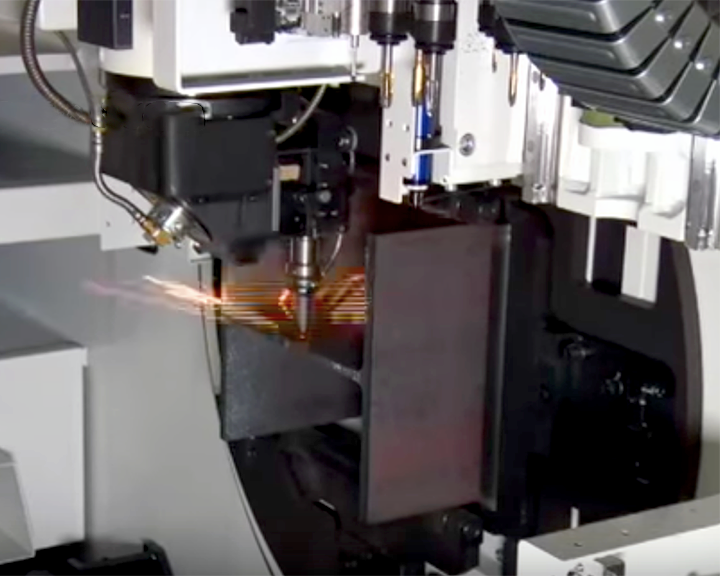

A Done-In-One® Laser Solution

Having all of these processes performed on one machine eliminates the need to have an operator work through these multiple steps moving the part from machine to machine. Less handling and movement equal reduced handling time

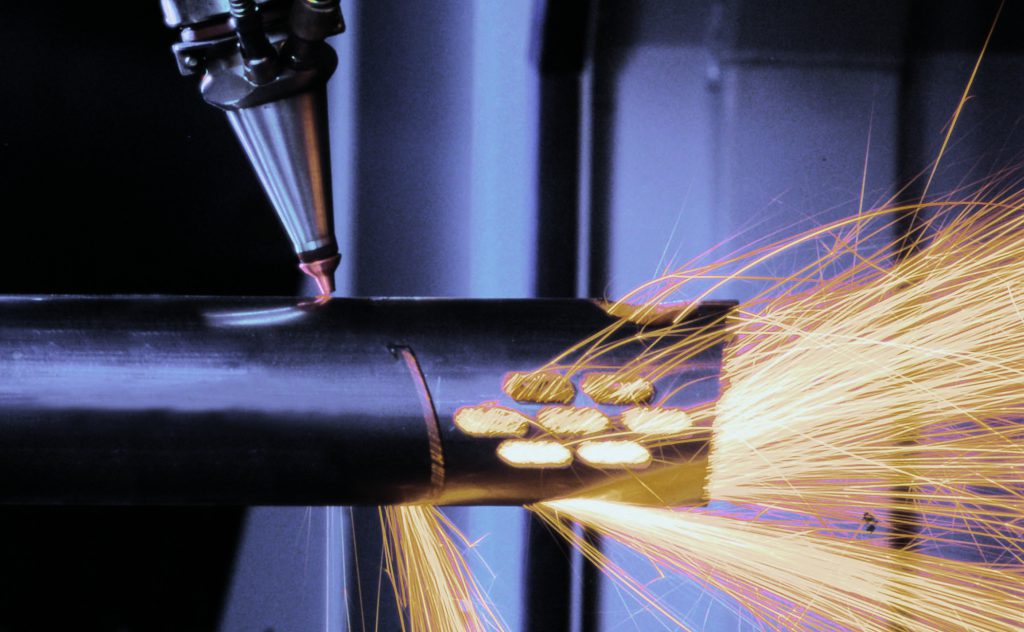

The Mazak 3D Fabri Gear 400 III excels at precision laser cutting a wide variety of tubes and pipes including round, square, rectangular, and triangular.

It can also process H, I, and L beams, C-channel, angle iron, and additional user-defined shapes from mild or stainless steel. The Mazak 3D Fabri Gear 400 III gives us the flexibility to handle jobs of all sizes.

The 6-axis Fabri Gear has an articulating head that makes it possible to produce a wider variety of cuts, precise angles, and beveled edges.

It can cut at any desired angle for weld prep, plus achieve the highest accuracy for easy fit-up of assemblies in a single program cycle

The Mazak 3D Fabri Gear 400 III is a workhorse offering an infeed of 15,000 mm/590 inches and an outfeed of 12,000mm/472 inches. It can cut round tube up to 16 inches in diameter and square tube up to 11.8 inches across.

The 4.0 kW Fabri Gear 400 III can cut through mild steel with a wall thickness up to 0.866-inch, stainless steel up to 0.383-inch thick, and aluminum up to 0.314-inch thick.*

*Material cutting thickness is dependent on many factors including material specifications, condition and machine parameters

In laser tube cutting, the real focus is part-processing time, precision, and efficiency not just cutting speed. The process includes loading a tube, indexing it into the right position, piercing and cutting it, and unloading the part.

You know what they say … never enough time to do it right but always time to do it over. We don’t want “do overs.”

The positioning of the tube’s weld seam has to be taken into account for laser cutting. The weld seam must not interfere with pins or holes, and for aesthetic applications, such as furniture, the weld seams need to be hidden as much as possible. Also, the weld seams also are of different compositions and cut differently than the rest of your tube.

With the Mazak laser, automatic controls adjust the power, frequency, and duty cycle as the laser works cuts through the tube—and its weld seam.

Service Steel has been supplying customers with laser cutting for 100 years.

Compared to regular steel. stainless steel does not easily corrode, stain, or oxidize/rust. Steel is available from Service Steel in a extensive range of forms, grades, finishes, gauges, widths, and lengths. Many different industries rely on stainless steel for a wide range of applications including aerospace, automotive, manufacturing, oil and gas, and many more. If you cannot find the exact type of steel you are looking for, please call or contact us.

Why Service Steel

The Service Steel Company, a steel tube, pipe, and bar service center, was organized in Detroit by Herbert B. Van Pelt and his son, Donald C. Van Pelt in 1920, and was headquartered at Rivard and Maple Streets tucked in between Eastern Market and Lafayette Park.

Through the years, Service Steel has remained solid under the ownership and direction of the Van Pelt family – 100 years after its founding.

Download Our Product Catalog & Reference Guide

SERVICE STEEL HAS BEEN DELIVERING QUALITY, VALUE, & COMMITMENT FOR 100 YEARS.

WE BUILD MUTUALLY BENEFICIAL RELATIONSHIPS WITH OUR CUSTOMERS.

5 LOCATIONS, EACH SERVING THE UNIQUE NEEDS OF REGIONAL CUSTOMERS.

Looking For Laser Cutting Services?

Our priority is our customer, so if you ever have a concern, question or comment please contact us and we will be more than happy to assist you to answer all your questions. We’ve helped thousands of companies just like yours.