Carbon Mechanical Tubing

Service Steel has been supplying customers with carbon mechanical tubing for 100 years.

We pride ourselves in knowing our customers’ needs as well as they do.

Service Steel has been supplying customers with carbon mechanical tubing for 100 years. We pride ourselves in knowing our customers’ needs as well as they do.

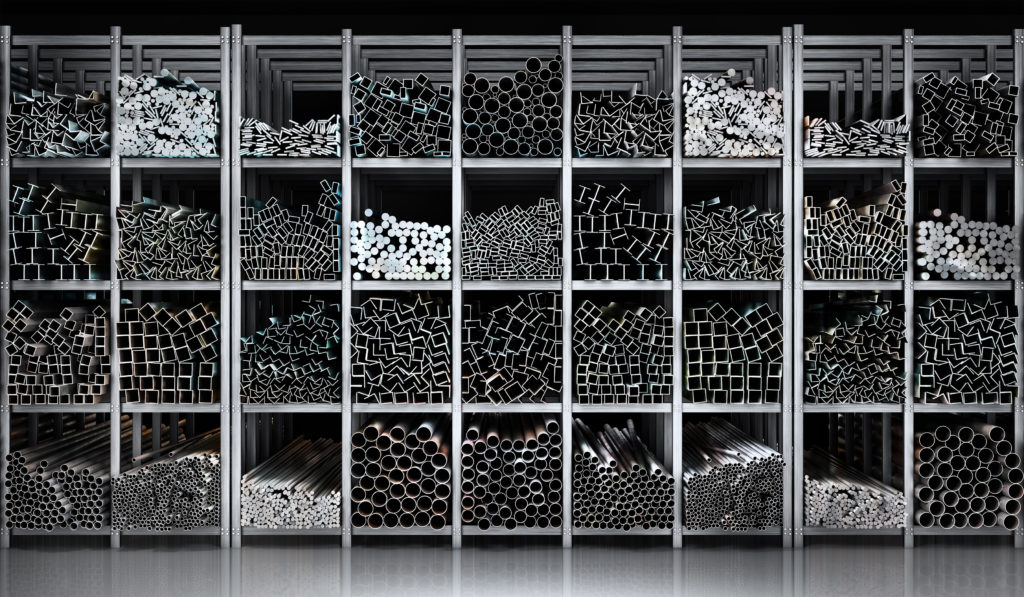

A Complete Line Of Carbon Mechanical Tubing For Multiple Applications.

Carbon steel mechanical tubing from Service Steel is available in a variety of shapes, diameters, walls, and lengths to meet your application needs. Custom orders are our specialty. Service Steel specializes in the hard to find and/or odd sizes of mild carbon and alloy tubing.

Talk to one of our sales associates about your specific application and we’ll cut and ship the right steel tubing at the right price at the right time. We are ready to deliver the specific steel tubing needed for your precise application.

- Hot Rolled Electric Resistance Welded (ERW) to ASTM A513-1

- Cold Rolled Electric Resistance Welded (ERW) to ASTM A513-2

- D.O.M to ASTM A513-5

- Cold Drawn and Hot Finished Seamless to ASTM A519 and A106

- Cold Drawn and Hot Finished Alloy 4130 & 4140 Grades

High Strength Low Alloy

Structural and carbon mechanical tubing have a lot in common at first glance.

What makes steel tubing mechanical or structural? The difference between the two types of tubing shows most clearly in their properties and their applications. Here’s how manufacturers classify these two types of tubing based on their end use.

TOLERANCE & SPECIFICATIONS

Mechanical Tubing is produced to strict tolerances and specifications (ASTM A513). Mechanical tubing requires much more precision than the structural stuff — its chemistry, measurements, and requirements are strictly laid out and adhered to, since its applications tend to be more sensitive than holding up a building. Seamless mechanical tubing can help avoid weak points in the component. Seamless tubes aren’t subjected to welding and therefore aren’t extra-prone to corrosion and such. Structural Tubing has looser requirements (ASTM A500). As its end uses are purely structural, this type of tubing needs to be strong and durable above all else. Tight tolerances and appearance are less important. Structural tube is often called HSS, or hollow structural sections.

FABRICATION

Both mechanical & structural tubing can be fabricated after production. This can include cutting, drilling, punching, bending, stamping, welding, and other secondary services.

SHAPES

Both mechanical & structural tubing can be shaped as rounds, squares, and rectangles. Additionally, mechanical tubing can be found in a variety of other shapes).

MEASUREMENT

Both mechanical and structural tubing are measured by inside dimensions (I.D.), outside dimensions (O.D.), and gauge (wall thickness).

COMPOSITION

Both mechanical & structural tubing can be made of: Carbon steel, Stainless steel, Galvanized steel and Other steel alloys… as long as the material is strong enough to stand up to stressful structural use.

APPLICATIONS

The main difference between mechanical and structural tubular steel products is how they’re used.

Mechanical tubing is used in a variety of applications that require specific measurements, as well as in very low-stress structural applications.

Mechanical tubing is most often used in machinery and tools for all industries, from automotive to agriculture. Other common uses for mechanical tubing include:

- Solar Panel Supports

- Conveyor Belt Components

- Industrial Machinery

- Playground Equipment

- Greenhouse Structures

- Restaurant, Kitchen, & Food Service Parts

- Hospital Beds & Medical Equipment

- Canopies and Other Recreational Stands

- Home & Garden Tools

Structural tubing is used in more high-stress, long-term, corrosive structural applications, such as:

- Infrastructure (Roads, Bridges, Buildings)

- Construction & Construction Equipment

- Sign Supports

- Drilling & Underwater Platforms

- Roll Cages

Check Our Blog

Service Steel Introduces Cincinnati, Ohio Steel Tubing Micro-Site

Service Steel proudly introduces its all-new Cincinnati, Ohio steel tubing micro-site. This is the second in a series of location based micro-sites designed to provide Service Steel customers with convenience and value.The brand new micro-site is designed to provide...

Featured Product: Carbon Mechanical Tubing

Featured Product: Carbon Mechanical Tubing Service Steel is a premiere steel tubing supplier that specializes in supplying Carbon Mechanical Tubing products to original equipment manufacturers and fabricators. These products are used across a wide range of...

Featured Product: Yellow Zinc Dichromate Tubing

Service Steel is a premiere supplier of Hydraulic and Pressure Tubing products including Zinc Dichromate Tubing, also known as Yellow Zinc Dichromate Tubing. Zinc Dichromate is a plating which acts as a protective agent in corrosive environments of many varieties....

SERVICE STEEL HAS FIVE REGIONAL LOCATIONS TO ADDRESS THE UNIQUE NEEDS OF EACH GEOGRAPHIC AREA.

DETROIT

13700 Sherwood

Detroit MI 48212

Phone 313.365.6500

Toll-free 800.275.8823

CINCINNATI

5170 Broerman Avenue

Cincinnati, OH 45217

Phone 513.242.6000

Toll-free 800.929.8823

EAST MOLINE

2930 Morton Drive

East Moline IL 61244

Phone 309.755.2151

Toll-free 800.323.1176

BUFFALO

333 Wales Avenue

Tonawanda, NY 14150

Phone 716.694.5200

Toll-free 800.447.6733

FARMINGTON

5636 County Road 41

Farmington, NY 14425

Phone 315.876.9009

Toll-free 800.447.6733

BUFFALO

333 Wales Avenue

Tonawanda, NY 14150

Phone 716.694.5200

Toll-free 800.447.6733

FARMINGTON

5636 County Road 41

Farmington, NY 14425

Phone 315.876.9009

Toll-free 800.447.6733

Why Service Steel

The Service Steel Company, a steel tube, pipe, and bar service center, was organized in Detroit by Herbert B. Van Pelt and his son, Donald C. Van Pelt in 1920, and was headquartered at Rivard and Maple Streets tucked in between Eastern Market and Lafayette Park.

Through the years, Service Steel has remained solid under the ownership and direction of the Van Pelt family – 100 years after its founding.

Download Our Product Catalog & Reference Guide

SERVICE STEEL HAS BEEN DELIVERING QUALITY, VALUE, & COMMITMENT FOR 100 YEARS.

WE BUILD MUTUALLY BENEFICIAL RELATIONSHIPS WITH OUR CUSTOMERS.

5 LOCATIONS, EACH SERVING THE UNIQUE NEEDS OF REGIONAL CUSTOMERS.

Looking For Carbon Mechanical Tubing?

Our priority is our customer, so if you ever have a concern, question or comment please contact us and we will be more than happy to assist you to answer all your questions. We’ve helped thousands of companies just like yours.